Latest news

Photo: Polar Life Haus / Hans Koistinen

16 August 2024

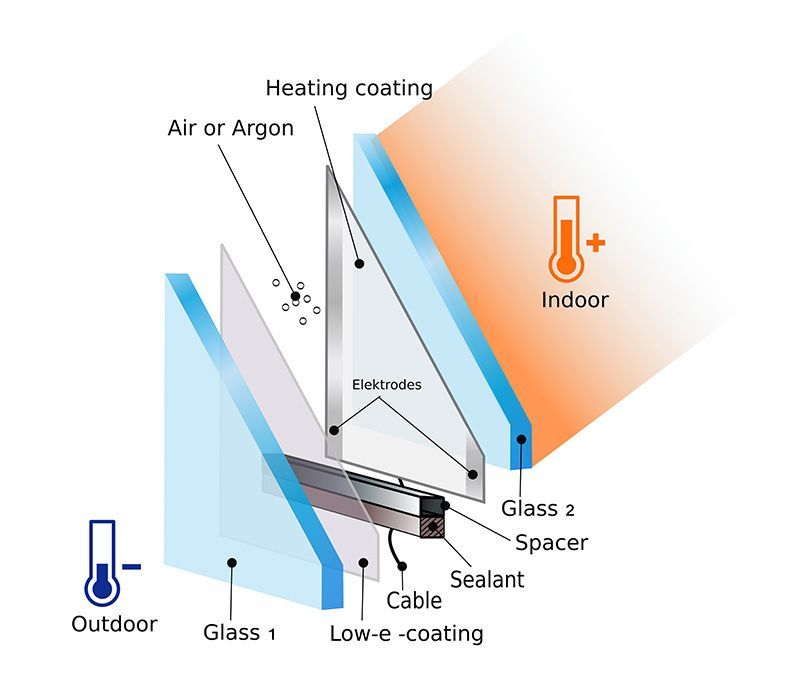

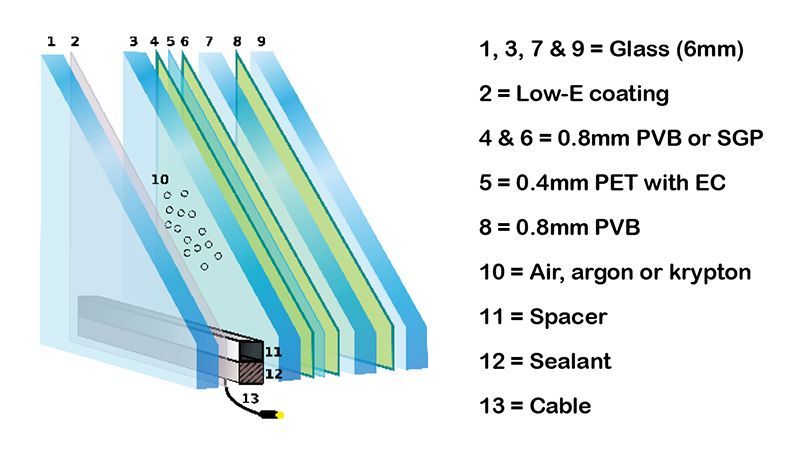

Our latest technical brochure for Finnglass Heated Glass is now available, showcasing a revolutionary approach to structural glass façades and window solutions. A big shout-out to Ingrid Hecht and her team at interview-international for their incredible work in bringing this brochure to life. Finnglass Heated Glass offers an energy-efficient solution, for example to the 'cold wall effect,' enhancing comfort and utility in indoor spaces while maintaining unobstructed views ✨of the natural world. This innovation is not just about aesthetics; it's about pushing the boundaries of what's possible in sustainable design and construction. For a closer look at how this technology is transforming real-world applications, we invite you to connect with our sales team and to visit our website www.finnglass.com to download the brochure. Stay tuned for more product updates as we continue to innovate and lead in the field of glass technology.

More interesting reads

More news

16 August 2024

Our latest technical brochure for Finnglass Heated Glass is now available, showcasing a revolutionary approach to structural glass façades and window solutions. A big shout-out to Ingrid Hecht and her team at interview-international for their incredible work in bringing this brochure to life. Finnglass Heated Glass offers an energy-efficient solution, for example to the 'cold wall effect,' enhancing comfort and utility in indoor spaces while maintaining unobstructed views ✨of the natural world. This innovation is not just about aesthetics; it's about pushing the boundaries of what's possible in sustainable design and construction. For a closer look at how this technology is transforming real-world applications, we invite you to connect with our sales team and to visit our website www.finnglass.com to download the brochure. Stay tuned for more product updates as we continue to innovate and lead in the field of glass technology.

16 April 2024

Finnglass launches new Bird Friendly brochure FGL Lintu-LaserTM. You can download the brochure here.

21 May 2021

Finnglass featured in Indoor climate seminar 2021 with subject CONTROL OF THERMAL CONDITIONS WITH ELECTRIC HEATED GLASSES.