Electrically Heated Glass

Heats up to keep glass clear of ice, snow and condensation*

Benefits

Unobstructed views

Enjoy your views free of ice, snow

and condensation

Indoor comfort

No drafts or cold-wall effect

next to big glass panels

Energy efficient

No drafts or cold-wall effect

next to big glass panels

Certified expertise

30 years of experience and

all parts certified for safety

Architectural freedom

Apply to facades, rooftops,

shaped glass, moving glass panes etc.

Easy to manage

Automate to react to weather,

no manual scraping

When to use our Electrically Heated Glass?

Melt ice and snow

Electrically Heated Glass melts ice and snow to prevent buildup on glass rooftops and skyscrapers, ensuring safety for inhabitants and all people around. Keep your views unobstructed and your indoors warm and comfortable, even in arctic conditions. We have considerable expertise and a long history in heated glass, as we introduced Electrially Heated Glass to our customers already in the mid-1980s.

Santa’s Hotel Aurora, Luosto, Finland

ButtonLångvik Spa, Kirkkonummi, Finland

ButtonAnti-condensation

Electrically Heated Glass is ideal for zapping condensation from the surface of glass in hot and humid conditions. The trick is to warm the surface of the glass to just a degree or two above dew point. Heating is usually installed on the outer glass in hot and humid climates, but can also be installed on the inner glass if humidity is on the inside, such as in swimming pools and spas.

Indoor comfort

Electrically Heated Glass prevents convection - the feeling of cold radiation and drafts when close to traditional glass without heating. This is also referred to as the "coldwall effect". It is caused by air close to the glass being cooler than in the rest of the room. Cold air descends, moves across the floor and rises back up, causing the sensation of cold radiation and drafts. When glass is heated to just one or two degrees higher than room temperature, it stops convection and heat loss through glass. This allows you to lower your room temperature without compromising comfort, leading to saving on energy and heating costs.

Levi Spirit Luxury Villa, Levi, Finland

ButtonMusiikkitalo, Helsinki, Finland

ButtonSave on space and construction costs

Radiators and fan coil units installed along the base of big glass walls can easily waste tens or even hundreds of square meters. They are usually installed to help reduce convection, but end up only moving it further away from glass while intensifying the sensation of drafts. With heated glass, you can eliminate convection without wasting space. You can save on construction costs of new buildings by eliminating fan coil units and unnecessary floor space, or retrofit an existing building to gain operational space.

How does it work?

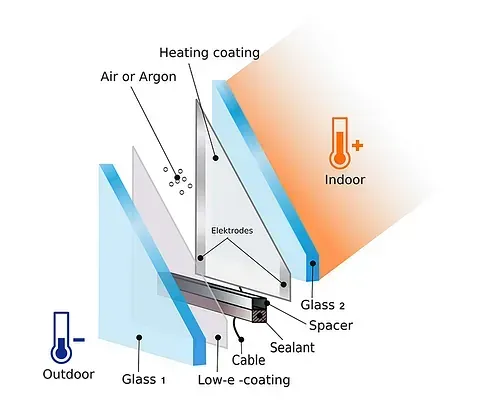

In the example, we have two tempered glass panes, each with a low-E coating. Electrode strips running along the edges of the inner glass lead electric current from a highly flexible double-insulated cable to the low-E coating.

The low-E coating acts as a uniform resistance element, warming glass evenly all across the pane. The second low-E coating on the exterior glass reflects escaping heat back indoors.

The Technical Research Center of Finland (VTT) concluded that over 90 percent of heat can be directed indoors, minimizing heat loss and your carbon footprint. This makes Electrically Heated Glass superior in energy efficiency to any other comparable technology.

Electrically Heated Glass product explosion image

ButtonTechnology in numbers

- U-factor: standard 0.5 – 1.0 W/m2K

- Efficiency: > 90 % of heat directed indoors

- Energy used for comfort heating: 20 – 100 W/m2

- Power for indoor and outdoor: 0 – 700 W/m2 (depending on use)

- Power for marine application: up to 3000 W/m2 (outdoor ship glass)

- Snow melting costs: ~ 1 Euro/m2/year (in Finland)

- Voltage: 0 – 400 V

*Check with our team to see how Electrically Heated Glass can benefit your project. Some technical limitations may apply.